Clients

JAG Process Solutions

CSL

Location

Melbourne, Australia

CORE CAPABILITIES

• Project management

• Stakeholder engagement and

management

• Factory acceptance testing

• Validation services

• Compliance services

• Good Manufacturing Practice

(GMP) compliance

Project Summary

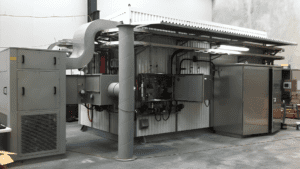

Synertec was engaged by JAG Process Solutions to deliver the independent validation and qualification of the automation control systems for a number of major pharmaceutical production facilities including:

- The new Privigen Module IV plant

- An upgrade of the existing Module III system

- The AlbuRx Facility Phase 3 project

The Challenge

JAG required an independent, experienced partner with a deep understanding of automation control systems and the complex processes of a pharmaceutical facility, and extensive experience in Good Manufacturing Practice (GMP) validation services.

Synertec’s Solution

Synertec worked with both JAG and CSL to develop testing strategies for the various operational qualification protocols required and to execute them on the live site. GMP procedures were followed as per CSL’s requirements to validate JAG’s software.

Developing and executing the operational qualification protocols required Synertec to build a detailed understanding of the existing Module III plant for Privigen and subsequent implementation into the Module IV testing. Operational qualification covered the following testing methodologies:

- Normal operation

- Negative testing

- Infrastructure

- Peripheral devices and remote terminals

- Electronic batch records

Synertec also developed protocols and executed factory acceptance testing for process control software with CSL and JAG. This involved checking CSL approved recipes and preparing piping and instrumentation diagrams and flow-path diagrams.