Client

Stolthaven / Koppers JV

Location

Newcastle, New South Wales

CORE CAPABILITIES

• Mechanical engineering

• Detailed design

• 3-Dimensional scanning

• In house production of 3D isometric drawings for fabrication

• Weld records and quality control

• Synertec accredited ISO45001 OHSE management system

Project Summary

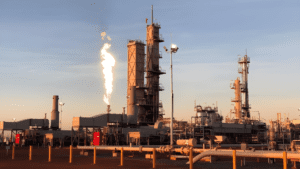

Stolthaven Terminals own and operate a bulk fuel import terminal at Mayfield in Newcastle, New South Wales built on the rehabilitated BHP steel mill site. In Stage 1 of the project, Synertec installed the mechanical pipework including a 1.7km long temporary wharf line for ship-toterminal transfers. Stolthaven / Koppers JV subsequently built a new liquids berth on the Hunter River and engaged Synertec for the Stage 3 Terminal expansion.

The Challenge

The complex project required the design, fabrication, erection, and commissioning of pitch and coal tar import pipelines for Koppers Carbon Materials and Chemicals. These pipelines were relocated to the new liquids berth, which required the relocation of more than 6.5km of new transfer pipework between the Koppers chemical reheat plant and their current site. This included over 3.5km of hot oil heating system running at 210 degrees Celsius.

Synertec’s Solution

Drawing on a wealth of experience in the design and construction of bulk fuel installations, Synertec quickly and efficiently designed, constructed, and commissioned the project to achieve the client’s tight timeframes. Innovative solutions such as prefabrication of pipe bridges that were subsequently craned into position allowed for the short program to be achieved while minimising costs.

Synertec designed, fabricated, erected, and commissioned the new 250mm and 300mm diesel pipelines from the new berth to the existing terminal, totalling approximately 1.5km of installed pipework. In a demonstration of Synertec’s exemplary safety record, there were no lost time injuries throughout the 13-month project duration.