Client

Xepa-Soul Pattinson

Location

Melaka, Malaysia

Core Capabilities

• Project management

• Specialist multi discipline engineering including process, mechanical, electrical, control, and automation engineering

• 3D modelling

• Commissioning

• Good Manufacturing Practice (GMP) validation and compliance services

• V-model engineering lifecycle analysis

• Construction support

Project Summary

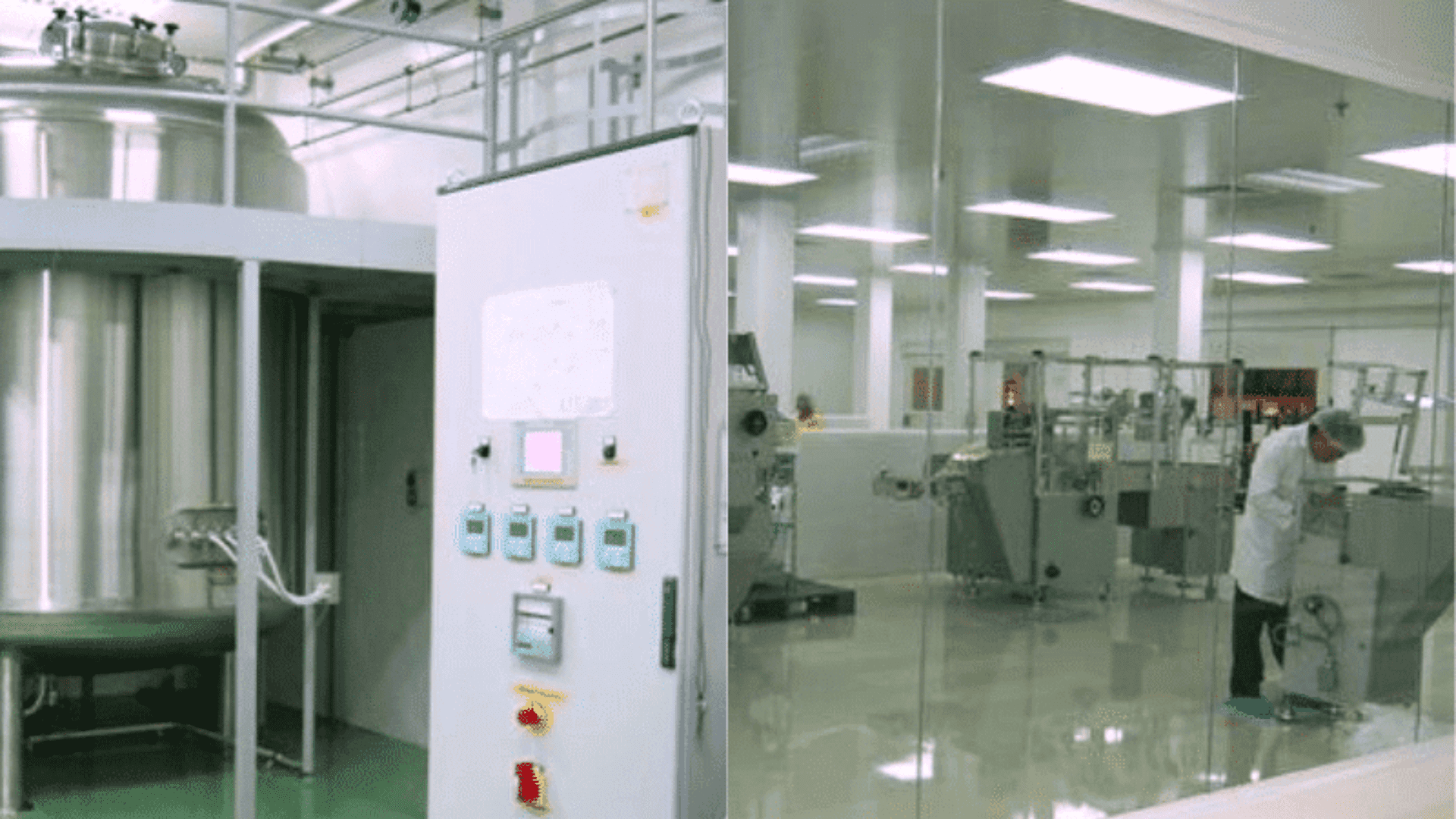

Xepa is the leading manufacturer of off-patent pharmaceuticals in Malaysia. To cater for increased product demand, Xepa constructed a new multi-purpose pharmaceutical manufacturing facility and associated infrastructure.

The Challenge

The project required process engineering and utility design expertise with a focus on lowering operating cost and footprint, while achieving certification for Good Manufacturing Practice (GMP).

Synertec’s Solution

Synertec was initially contracted to undertake a Front End Engineering Design (FEED) study, which then progressed to detailed design and validation work incorporating:

- Equipment selection including purified water system

- Process flows

- Personnel flows

- Manufacturing facility layouts

- Wall and floor finishes and details

- Environmental control, including heating, ventilation, air conditioning, chilled water, and extraction systems

- Electrical design

- Automation systems

Synertec introduced innovative solutions for manufacturing processes and design layouts, which optimised space usage and decreased operating costs. Synertec also provided technical overview and support during construction.