Client

Chevron Australia

Location

North West Shelf, Western Australia and Melbourne, Australia

Core Capabilities

- Specialist multi-discipline

engineering including

instrumentation, electrical,

process, mechanical, and

automation engineering - Detailed design of equipment,

hardware, and software - Project management

- Construction management

- Factory acceptance testing

- Site acceptance testing

- Commissioning

- Operational and maintenance

training

Technologies

- Emerson 700XA gas

chromatographs - Krohne load out computer system

- Allen-Bradley ControlLogix

programmable logic controls and

human machine interface - Opta-Periph vaporisers and gas

holder - SilcoNert 2000 coated electropolished tubing

Project Summary

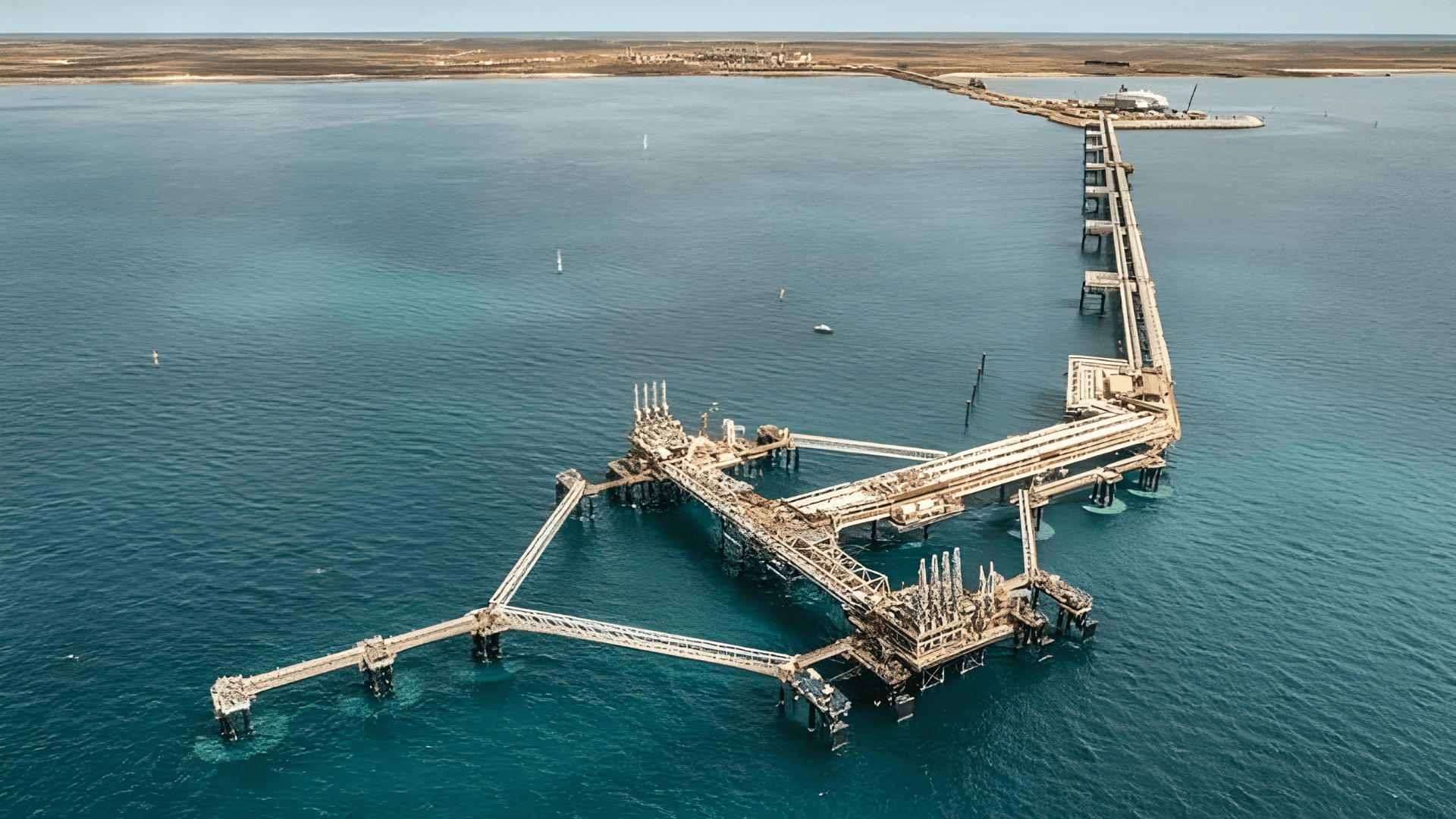

Chevron Australia’s Gorgon natural gas project in Western Australia comprised the development of the Greater Gorgon gas fields, subsea gas-gathering infrastructure, and a Liquefied Natural Gas (LNG) plant on Barrow Island.

The Challenge

An LNG lifting agreement was in place outlining the LNG custody transfer rules for the project, and the pre-existing design for the LNG loading system did not meet the commercial requirements of the agreement.

Chevron needed a partner to identify the issues with the design and rectify the deficiencies in the system. An added challenge was the location of the LNG plant on the remote and sensitive Barrow Island, which is a protected nature reserve subject to strict quarantine rules.

Synertec Solution

Synertec carried out a gap analysis that identified how to rectify the LNG loading system and ensure its compliance with the LNG lifting agreement and other relevant standards.

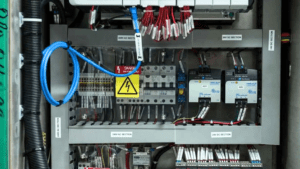

The solution involved a continuous sampling system with built-in

redundancy that could take a representative sample of an LNG load for measurement and analysis in the field, in the lab, or at the end destination.

The scope of work delivered by Synertec included the detailed design, construction, testing, and quarantine compliance of:

- LNG composite sampling vaporisers

- LNG composite sampling system

- Manual spot sampling points for compositional analysis and impurities

- SilcoNert 2000 coated electro-polished tubing

- LNG composite analyser house

- Gas chromatographs

- Sample conditioning systems

- Remote Inputs and Outputs (I/O’s)

- Calibration gas cabinet