Australia Pacific Liquefied Natural Gas Project

Published May 24, 2024

Client

- Bechtel Oil and Gas

Location

- Queensland, Australia

Core Capabilities

- Specialist multi-discipline engineering including instrumentation, electrical, process, mechanical, and automation engineering

- Metering, control, and online measurement systems

- Integrated solution products from a range of manufactures

- Project management

- Construction management

- Factory acceptance testing

- Site acceptance testing

- Commissioning

- Ongoing support and maintenance

Get in touch today to see how Synertec could help you with your next project.

Project Summary

Australia Pacific LNG (APLNG) is Australia’s largest producer of Coal Seam Gas (CSG), eastern Australia’s largest producer of natural gas, and hold the greatest CSG reserves in Australia. APLNG process CSG into Liquefied Natural Gas (LNG) and are a major exporter of LNG to Asia.

A major global player in the oil and gas industry, Bechtel Oil and Gas selected Synertec as their supplier for the analyser systems for the APLNG facility.

The Challenge

The project required fully automated online analyser systems to provide critical in-process control, quality control, and quality billing. For their project partner, Bechtel needed a firm of specialist multi-discipline engineers to design and build a bespoke system supporting the ultimate capacity of four LNG trains.

The first two operational LNG trains have a processing capacity of nine million tonnes per annum.

Synertec's Solution

Synertec’s project scope involved the design, engineering, project management, construction, and testing of the following items:

- Six fully air conditioned analyser houses with a fire and gas system certified for installation in a Zone 2 Hazardous Area. The analyser houses contained a total of 28 gas chromatographs, 2 analysers, 5 flow computers and 1 LNG sampler

- Four Quartz Crystal Microbalance (QCM) analysers to measure moisture content at extremely low Parts Per Million (PPM) concentrations. Each analyser was housed in a three-sided shelter including electrical equipment compliant with Zone 2 Hazardous Area requirements

- Thirteen Tunable Diode Lasers (TDL) to measure moisture levels and carbon dioxide concentrations

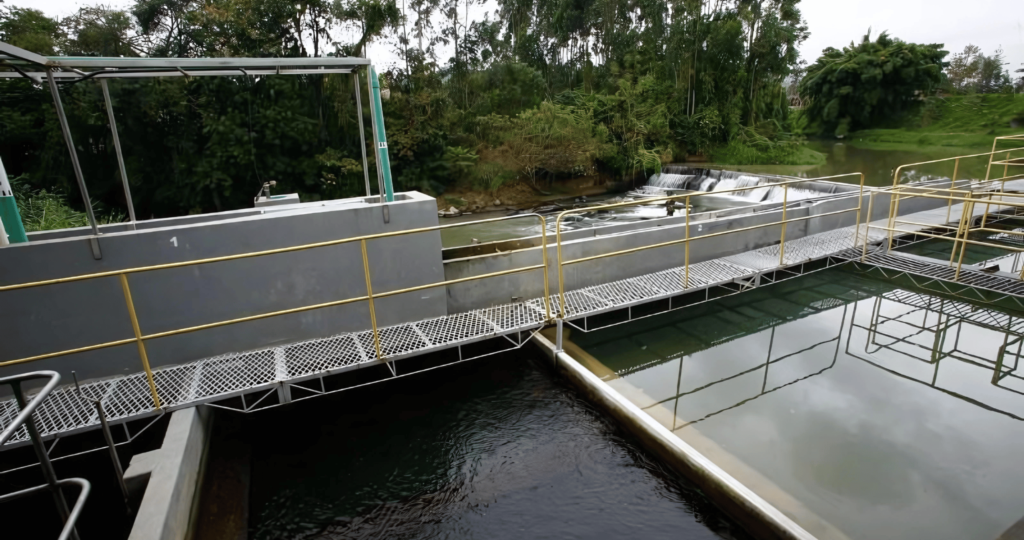

- Four water quality analysers to measure pH levels, chlorine, conductivity, turbidity, and oil content in water samples

- Sample probes including fixed, manual, and automatic insertion strategies, and LNG probes.

The completed project achieved compliance with all Australian standards for installation in Zone 2 Hazardous Areas and cyclone rated areas.