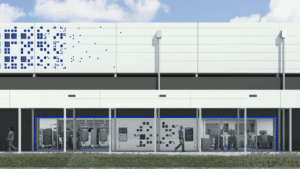

Biological Vaccines

Manufacturing Facility

LOCATION

Hyderabad, India

Core Capabilities

- Project management

- Specialist multi-discipline engineering including process, mechanical, electrical, control and automation engineering

- 3D modelling

- Commissioning

- Good Manufacturing Practice (GMP) validation and compliance services

- V-model systems engineering lifecycle analysis

- Construction phase support

Project Summary

Merck / Bio E required support and expertise for the fit-out of a new pharmaceutical manufacturing suite within an existing building.

The Challange

Working within the challenging site constraints of an existing facility, specialist engineering strategies were required to meet the complex design and construction requirements of a pharmaceutical suite to manufacture conjugated vaccines in a production environment compliant with the requirements of the United States Food and Drug Administration (FDA).

Synertec’s Solution

Synertec provided resources for project management, construction management, commissioning, and qualification services to deliver the design, procurement, construction, and validation of a new suite for the manufacture of conjugated vaccines to meet FDA compliance and approval.

The new facility, with full High Efficiency Particulate Air (HEPA) filtration and containment zones for fume control, incorporated the following main processes:

- Preparation and washing: glass washer

- Sterilisation: autoclave

- Dissolution and homogenisation: glass vessels and

homogeniser - Ultrafiltration: Tangential Flow Filtration (TFF) skids

- Conjugation: glass reactors

- Final purification: TFF skids, buffer tanks

- Waste treatment: cyanide treatment skid